Hello, Welcome to Ever Power!

Hello, Welcome to Ever Power!

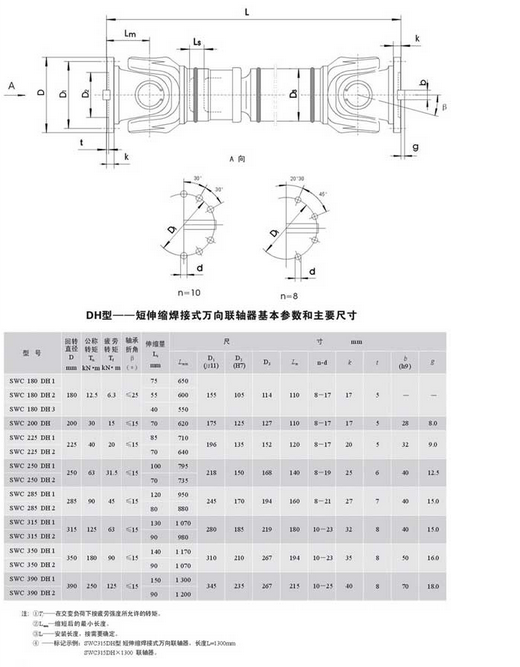

SWCCH single telescopic welded coupling

XNUMX. Applicable scope

十字轴式万向联轴器主要适用于轧制机械、起重运输机械以及其它重型机械,联接两个不同轴线的传动轴系。SWP型回转直径为160-640mm,公称转矩为16-1250KN.m,轴线折角A-F型≤10°,G型≤5°;SWC型回转直径为100-620mm,公称转矩为1.25-1000KN.m,轴线折角为15°-25°。

XNUMX. Connection method of universal coupling

The universal coupling uses high-strength bolts and self-locking nuts to connect the flanges at both ends to other mechanical components. The transfer torque is transmitted through the friction between the flange face key and the flange. SWP type related connection dimensions and bolt pre-tightening torque are in accordance with the regulations in Figure XNUMX and Table XNUMX; SWC type related connection dimensions and bolt pre-tightening torque are in accordance with the regulations in Figure XNUMX and Table XNUMX.

The bolts can only be inserted from the flange side that matches the coupling. The nuts are tightened from the flange side of the universal coupling. The mechanical properties of the bolts meet the 3098.1 level in GB10.9, and the mechanical properties of the nuts should meet GB3098.4. Level 10 regulations in XNUMX.

Third, the use and maintenance of universal coupling

1. Before installing the universal coupling, clean the two end faces and check the fit of the key grooves on the end face, and then tighten the screws so that they are not allowed to loosen;

2. After the universal coupling is installed, run a shift normally, check all the fastening screws, and if they are found to be loose, tighten them again with the specified tightening torque. Repeat this for several shifts to ensure that they will not loosen;

3. The sliding surface, crosshead, bearing, etc. of the universal coupling are guaranteed to be lubricated. Generally, 2# industrial lithium-based grease or 2# molybdenum disulfide calcium-based grease is used. Under normal conditions, it can be operated continuously for 500 hours. Refuel once a month. If working under high temperature conditions, refuel once a week. When refueling, unscrew the oil hole screws on the bearing end face and inject it with a high-pressure oil gun until overflow;

4. The universal coupling must be maintained once after 3 months of use. If normal wear such as indentation is found, it should be replaced in time;

5. In order to prolong the service life of the universal joint, during maintenance, disassembly and washing, the cross shaft is rotated 180° to achieve alternate use of the journal force;

6. Long-term overload use and operation accidents should be avoided;

7. During work and operation, you should always observe whether the universal joint has abnormal radial swing and bearing heating, etc., and repair these phenomena in time;

8. Appropriate protective measures should be adopted in various places where personal and equipment accidents may be caused by the operating universal coupling.