Hello, Welcome to Ever Power!

Hello, Welcome to Ever Power!

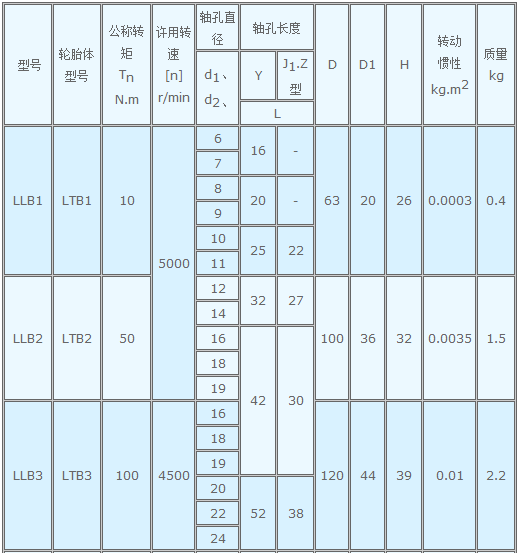

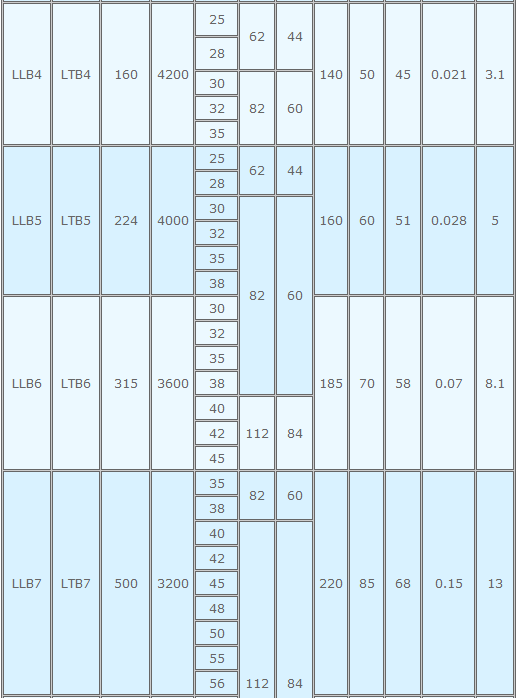

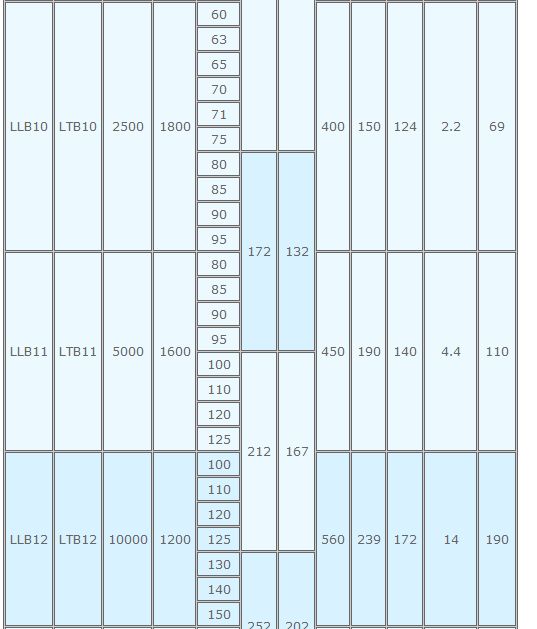

Tyre coupling

Tire coupling tire body is one of the spare parts of tire coupling, correspondingly divided into UL, LA, LB tire body.Tire couplings are divided into two categories: convex and concave. The convex is divided into three types: integral with frame, integral without bone and radial incision.The inner side of the tire ring is bonded to the steel frame by a vulcanization method, and the bolt holes on the frame are welded with nuts.When assembling, bolts are used to connect the flanges of the two coupling halves. The friction force generated between the tire and the flange end faces by tightening the bolts is used to transmit torque. The torsional shear deformation of the tire ring occurs when the tire ring is working, so the tire coupling It has high elasticity, a large ability to compensate the relative displacement of the two shafts, and has good damping, and has a simple structure, does not require lubrication, and is relatively convenient for assembly and disassembly and maintenance.The disadvantage is that the bearing capacity is not high and the external dimension is large. As the relative torsion angle of the two shafts increases, the tire shape is twisted, and the axial dimension is slightly reduced, which will generate a large additional axial force on the two shafts. Increase the bearing load and reduce the life.When the tire coupling is running at high speed, the outer edge of the tire expands outward due to the centrifugal force, which will further increase the additional axial force.For this reason, measures should be taken when installing the coupling to make the direction of the stress in the tire opposite to the direction of the stress generated during work, so as to offset part of the additional axial force and improve the working conditions of the coupling and the two bearings.